Documentation page: https://vutlan.atlassian.net/wiki/spaces/DEN/pages/1834713171/VT500+Temperature+sensor+v2

Product page: https://vutlan.com/digital-output/14-vt500-temperature-sensor.html

Function and purpose

The sensor is needed for the measurement of temperature indoors.

"VT500 / Temperature sensor" is an analog plug&play temperature sensor for indoor use only. Can be connected to any of the analog ports (A1...A8) of Vutlan monitoring systems.

The accuracy of the sensor is ± 0.15 °C at room temperature. The maximum distance from the monitoring unit (or sensor extension unit) is 100 meters.

The maximum amount of sensors and maximum length can be extended using the "VT408 / Sensor extension unit".

The sensor can not be used on its own. It must be used together with Vutlan monitoring systems.

Technical specifications

Feature | Description |

|---|---|

Type | Analog sensor |

Usage | Temperature measurement |

Product dimensions | (Length, Width, Height) 60×18×18 mm |

Packing weight | 70 g |

Packing size | (Length, Width, Height) 45x45x120 mm |

Cable length | 2m (the custom length of the cable is possible) |

Power Consumption | 60 mW |

Operating temperature | Optimal temperature range: -10° C to +80° C Extended temperature range: -40° С to +100° C |

Operating humidity | 0 to 95 % |

Storage temperature | -40° С to +100° C |

Storage humidity | 0 to 95 % |

Mounting possibilities | Desktop, Indoor, Rack-mountable, Wall mount |

Max. distance from the unit | 100 m |

Manufactured in (country) | Manufactured in Slovak Republic, E.U. |

HS Code | 9025 11 800 |

Accuracy | ± 0.15 °C at room temperature |

Daisy chain | Not possible |

Inputs terminals | RJ-11 / 6P4C |

Package includes

Package content | Description | Quantity | |

|---|---|---|---|

1 | Sensor | 1 pc | |

2 | RJ11 6P4C 2m telephone cable | 1 pcs | |

3 | Screw B4,2 x 16 | ||

4 | Sticker |

Feature | Description |

|---|---|

Packaging weight | 70g |

Packaging size | (Length, Width, Height) 45x45x120 mm |

Drawings

Connecting the sensor

The sensor uses a standard Vutlan analog RJS5 RJ11 sensor cable for connecting to the monitoring unit.

Analog sensor connection

This section includes child pages:

- VT410 / DC voltage monitor

- VT420 / Converter 4-20mA

- VT500 / Temperature sensor

- VT510 / Humidity sensor

- VT501 / Outdoor temperature sensor

- VT520 / AC voltage monitor

- VT520DIN / AC Voltage monitor (link)

- VT530 / Access sensor

- VT540 / Vibration sensor

- VT550 / Wind velocity meter

- VT560 / Smoke detector

- VT570 / PIR sensor

- VT572 / Radar microwave motion sensor

- VT591 / Leak sensor & WLC / Leak detection cable

- VT593 / Spot leak sensor

- VT594 / BMS leak water sensor

- Chain connection of analog sensors

Connecting analog sensors

Connect the analog sensor by a supplied RJ-11 (6P4C) cable to any analog port "A1 .. A8" or "Sensor" port. The determination of the sensor type and connection will occur automatically.

If strong electromagnetic interference is present, we recommend using a 3-pair cable CAN FTP for sensor connection!

6P4C RJ11 cable wiring/pinouts

1- Yellow, 2- Green, 3- Red, 4 - Black

Colors are true for this telephone cable. Both ends match the colors and pinouts (identical).

Please refer to the RJ connectors comparison table:

Daisy chain connection

Some of the analog sensors can be connected to a daisy chain. Please refer to the article "Chain Connection of analog sensors".

Maximum cable length test

ok = tested

x = failed

Model | 50m | 100m | 120m | 150m | 200m | |

|---|---|---|---|---|---|---|

VT407 | AC current converter | ok recommended | ok | |||

VT410 | DC voltage monitor | ok | ||||

VT420 | Converter 4-20mA | ok recommended | ok | |||

VT500 | Temperature sensor | ok | ok | |||

VT501 | Outdoor temperature sensor | ok | ok | |||

VT510 | Humidity sensor | ok | x | |||

VT530 | Access sensor | ok | ||||

VT540 | Vibration sensor | ok | ||||

VT550 | Wind velocity meter | ok | x | |||

VT560 | Smoke detector | ok | ||||

VT570 | PIR sensor | ok | ||||

VT590 | Spot water detector | ok | ||||

VT591 | Water leak sensor | ok |

Extending the number of analog sensors

Using CAN extension "VT408 / Sensor extension unit" it is possible to increase the number of analog sensors connected to the monitoring unit up to 80 sensors.

Additional articles of interest

Installation using a sticker and a bracket

Option 1.

There's a round bump at the bottom of the plastic enclosure of the sensor. It is used for fastening when the sensor is mounted on walls using a screw. In the current example, it is not needed. If you are planning to mount a device differently, do not follow this step.

Cut the round bump using a knife so that the bottom of the plastic enclosure will be flat.

Option 2.

a) Stick the mounting sensor to the surface using the sticker.

or

b) Stick a sensor to the surface using a screw.

Option 3.

Mount the sensor to the surface using a mounting bracket. The mounting bracket and the sensor can be either attached by the stickers or together with screws and nuts.

Sensor configuration

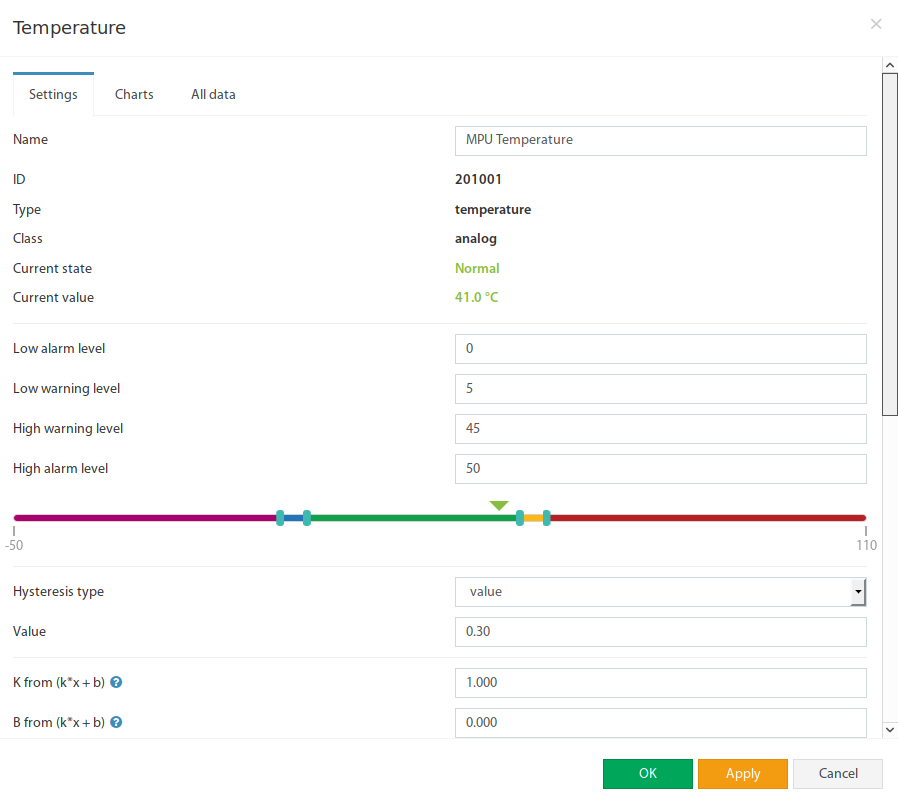

Settings tab

To configure a sensor, go to "Main menu" >> "System tree" and click on the sensor element in the tree. A modal window with sensor properties will pop up. Change the needed settings and click "OK" or "Apply" at the bottom of the "Properties" window.

All sensors include:

1 | Name | The name is given by the system automatically. You can change it to anything you want. |

3 | ID | System ID of the element. |

4 | Type | Examples: temperature, humidity, vibration. |

5 | Class | Examples: analog, CAN, switch, discrete. |

6 | Hardware port | The external port number on the device panel to which the sensor is connected (if the sensor is external). |

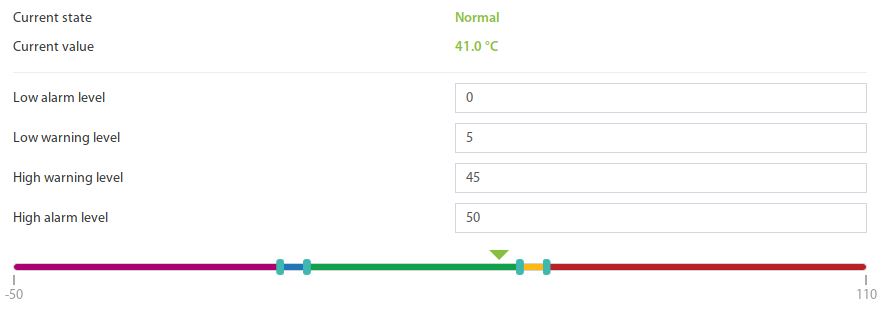

All sensors have threshold controls:

In the picture above, the "Current value" equals 41.0 and is represented by the small triangle. Currently, the triangle is green because it is situated in the "Normal" range. Hence the sensor says that the "Current state" is "Normal". This value is used by the system's "Logic schemes" menu to notify the administrator or take action.

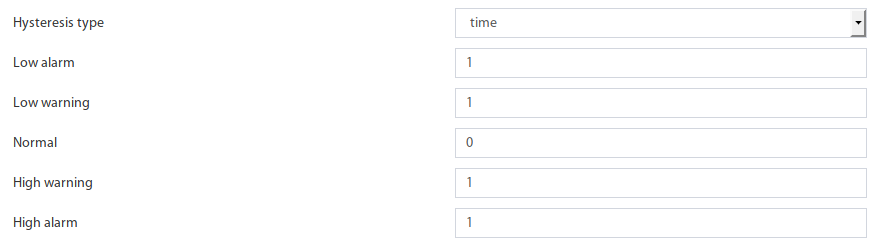

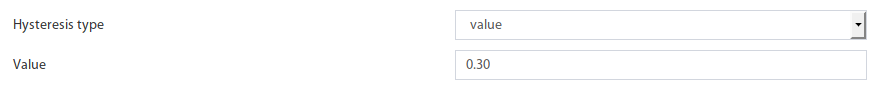

Hysteresis

Sensors have the option of setting the hysteresis state. Hysteresis can be a time, a value or it can be disabled.

If the hysteresis is set in time, the sensor will transmit to a new state with a delay of the specified number of seconds in the corresponding field. The time counting will begin from the moment when the measured value of the sensor has left the current range.

Each state has its own field. Which determines the time that the sensor value must continuously hold for the state to change to the specified.

If you set the hysteresis by value, the sensor transition to a new state will occur when the measured value of the sensor exits beyond the current range, adjusted for the specified hysteresis value.

You can calibrate the sensors. Use K and B coefficients. After the calibration, please, save the values in flash memory.

To save sensor properties in the device's flash memory press " " then "OK" to confirm.

Example: Why do we need to use Hysteresis

Let’s say that we have a temperature sensor. Let’s say that we have set up threshold values.

We have set the value 25.5 °C to be a threshold value between Normal/Alarm states.

If the temperature drops just below 25.5 °C You will have a “Normal” state.

If the temperature goes just above 25.5 °C You will have a “Warning” state.

Sometimes the temperature may stay at 25.5 °C and jump up and down by 0.1-0.3 °C. In this case, You will get too many notifications that the sensor is showing a Warning or Normal state.

In this case, we need to use a Hysteresis.

If the type “time” is chosen, the system will wait for a specified time before the State of the sensor is declared.

If type “value” is used, unless the temperature drops by a larger amount than specified, the sensor state will not be declared.

Tuning the sensor value

Sensor readings can be tunned by a linear formula "y = k * x - b"

Example VT407 + HAT-100Q1 / AC current converter:

Metered current for HAT: from 0 to 100A (This means that the range equals 100, k = 100)

The output of VT407 is 0-5V (That means that the range is equal to 5)

"b" = the value that the sensor shows in WebUI when there's no current. Let's say that b = + 0.021

You should use the following formula for HAT: 100/5*(x-y)

The expression formula would be 20*(x-0.021)

Point is used as a decimal separator (3.14)

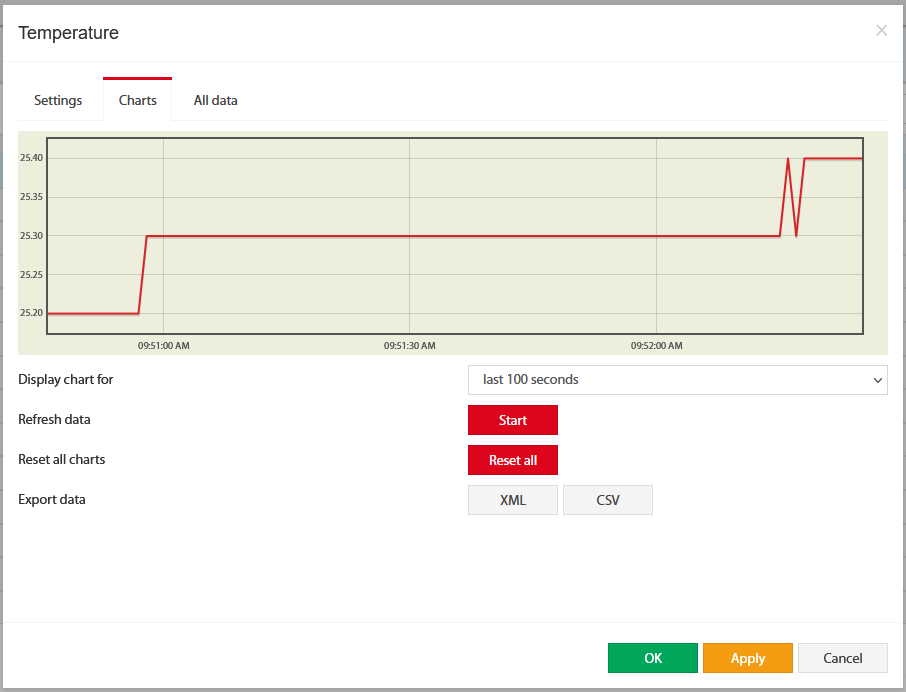

Charts tab

The charts tab shows the following:

Display chart for |

| |

Refresh data | Start | Poll a sensor |

Reset all charts | Reset all | Clears all saved data for the sensor. |

Export data | XML or CSV | Exporting data through WebUI does not work for more than a couple of days and is very rough. If you need detailed log data, use the logging of sensor values to the media. Note: Make sure no endpoint security services used in the network are not blocking the download of XML and CSV files. |

Reset smoke sensors

If analog sensors like VT560 / Smoke detector/ sensor detects smoke or fire, it will go into Alarm mode. Alarm mode can only be switched off manually using the Reset smoke detectors panel or using the onboard sensor Analog sensor power reset is found in the System tree >> Onboard.

Copyright:

Vutlan s.r.o. (LLC)

Remote Infrastructure Monitoring and Control

43 ul.Svornosti, 821 06 Bratislava,

Slovak Republic

www.vutlan.com

.jpg?version=2&modificationDate=1648112668410&cacheVersion=1&api=v2)

.jpg?version=2&modificationDate=1648112688375&cacheVersion=1&api=v2)

.jpg?version=1&modificationDate=1707204636707&cacheVersion=1&api=v2&width=760&height=433)

%20pinouts%20cable.jpg?version=1&modificationDate=1707204779856&cacheVersion=1&api=v2&width=760&height=431)

.jpg?version=2&modificationDate=1707204813374&cacheVersion=1&api=v2&width=723&height=579)

.jpg?version=1&modificationDate=1610547510940&cacheVersion=1&api=v2&width=396&height=337)