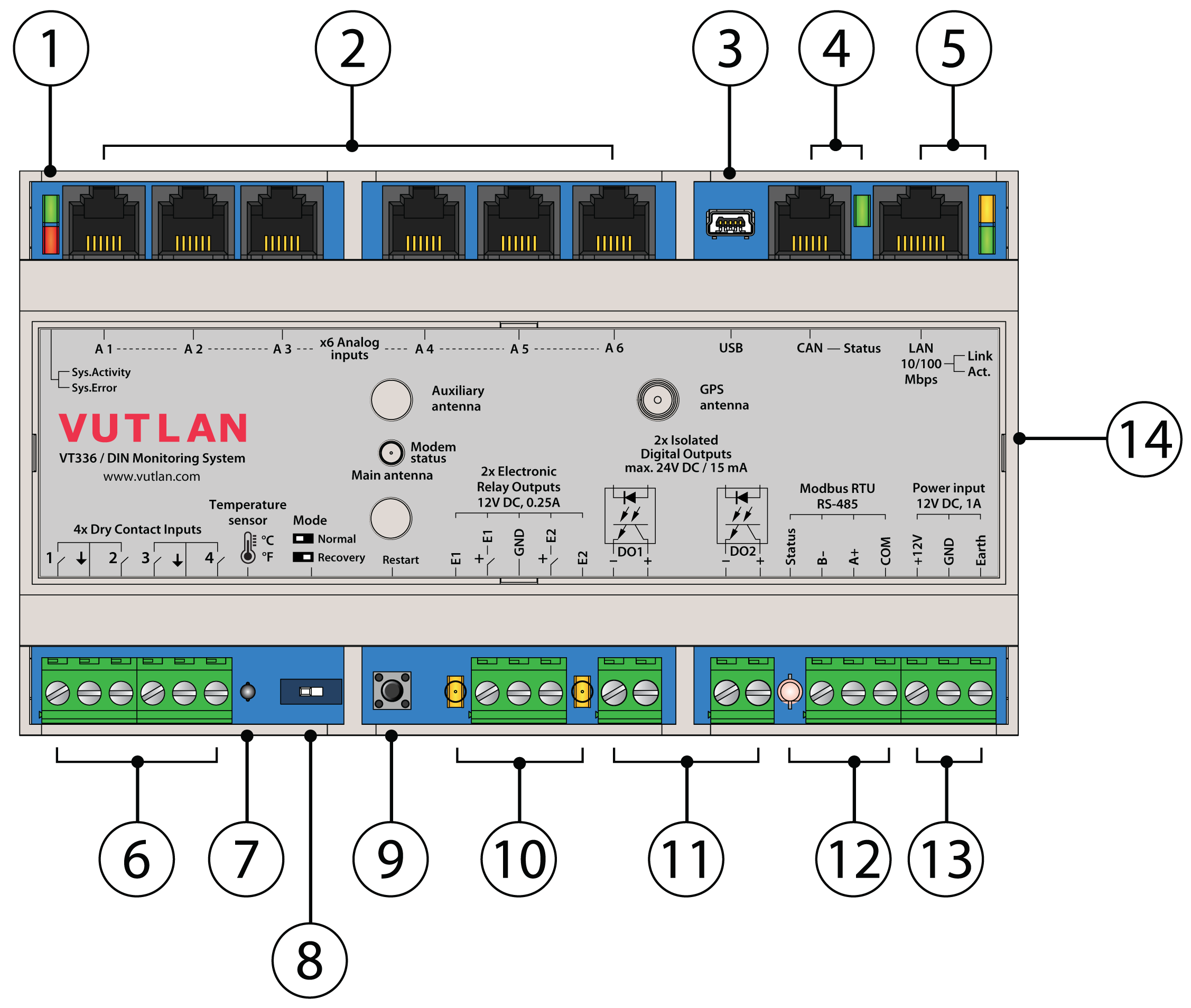

Functional description & components

1. "LED: ACTIVITY" - green LED indicates appliance status

"LED: ERROR» - red LED indicates system error and traffic.

2. "Analog sensors: A1..A6" - x6 RJ12 analog sensor inputs with auto-sensing. Read instructions at "Analog sensors connection", "Sensor configuration".

3. "USB" - type miniAB USB-port 2.0, required to connect a USB camera, USB flash, USB hub or to restore an appliance using USB flash.

4. "CAN" - digital connector RJ12 for the connection of CAN sensors and CAN extensions on a CAN bus, with auto-sensing. Read instructions at "CAN devices connection", "Setting up CAN".

- "CAN Status" - LED for digital bus sensors:

- The LED blinks slowly - nothing is connected

- The LED blinks fast - configuration is in process

- The LED glows constantly - connected to CAN devices

5. "LAN port" - Ethernet 10/100 Base-T port, provides an Ethernet connection.

- "LAN Link" - orange LED for Ethernet port. It shows network traffic.

- "LAN Activity" - green LED for Ethernet port. It shows network traffic. Flashes green when the system starts up. Shows the connection state (constant green light - the connection is established, blinking green - the connection attempt).

6. "DRY CONTACT INPUTS 1...4" - Digital inputs. Read instructions at "Connecting dry contacts", "Dry contacts settings".

7. "TEMPERATURE SENSOR" - accuracy +/- 1 °C.

8. "MODE" - a DIP switch for changing system modes.

- Normal mode 🠀: Normal operating state. The system should be always switched to this.

- Recovery 🠂: Turns a recovery mode On. Use this option only in case you need to recover manufacturing settings. Read instructions at "Factory settings recovery".

9. "RESTART" - button restarts the appliance. Press the button for several seconds.

10. "OUTPUT 12V 0.25A" - 12V 0.25A output electronic relay terminal. Read instructions at "Connecting 12V devices to 12V outputs".

11. "ISOLATED DRY CONTACTS OUTPUTS 1...4" - Digital outputs 24VDC / 15mA (type OUT). Read instructions at "Connecting dry contacts", "Dry contacts settings".

12. "RS-485 MODBUS RTU" - port for connecting Modbus RTU / RS-485 sensors and devices. Read instructions at "Connecting Modbus RTU sensors to VT336 & VT336PoE", "Configuring Modbus devices".

- "RS-485 Status" - LED for displaying Modbus RTU port status.

13. "DC 12V 1A" - DC power input. Instructions are in the section below.

14. "Modem" - "VT770 / LTE, GPS modem" is ordered separately. Read instructions at "Connecting VT770 / LTE modem with GNSS", "Network: LAN, GSM, LTE, RADIUS, DNS, SSL, VPN".

- "Modem status" - LED displays modems status.

- "SIM card slot" - Open the top cover to insert a SIM card.

- "GSM, LTE main antenna" - Connect GSM or LTE main antenna.

- "LTE auxiliary antenna" - Connect LTE auxiliary antenna (Auxiliary LTE antenna and antenna output are ordered separately from the modem). It helps to establish a stronger and more stable signal.

- "GPS active antenna" - GPS antenna and antenna output are ordered separately from the modem. Allows to set the time using GPS and shows the location of the device on the map.

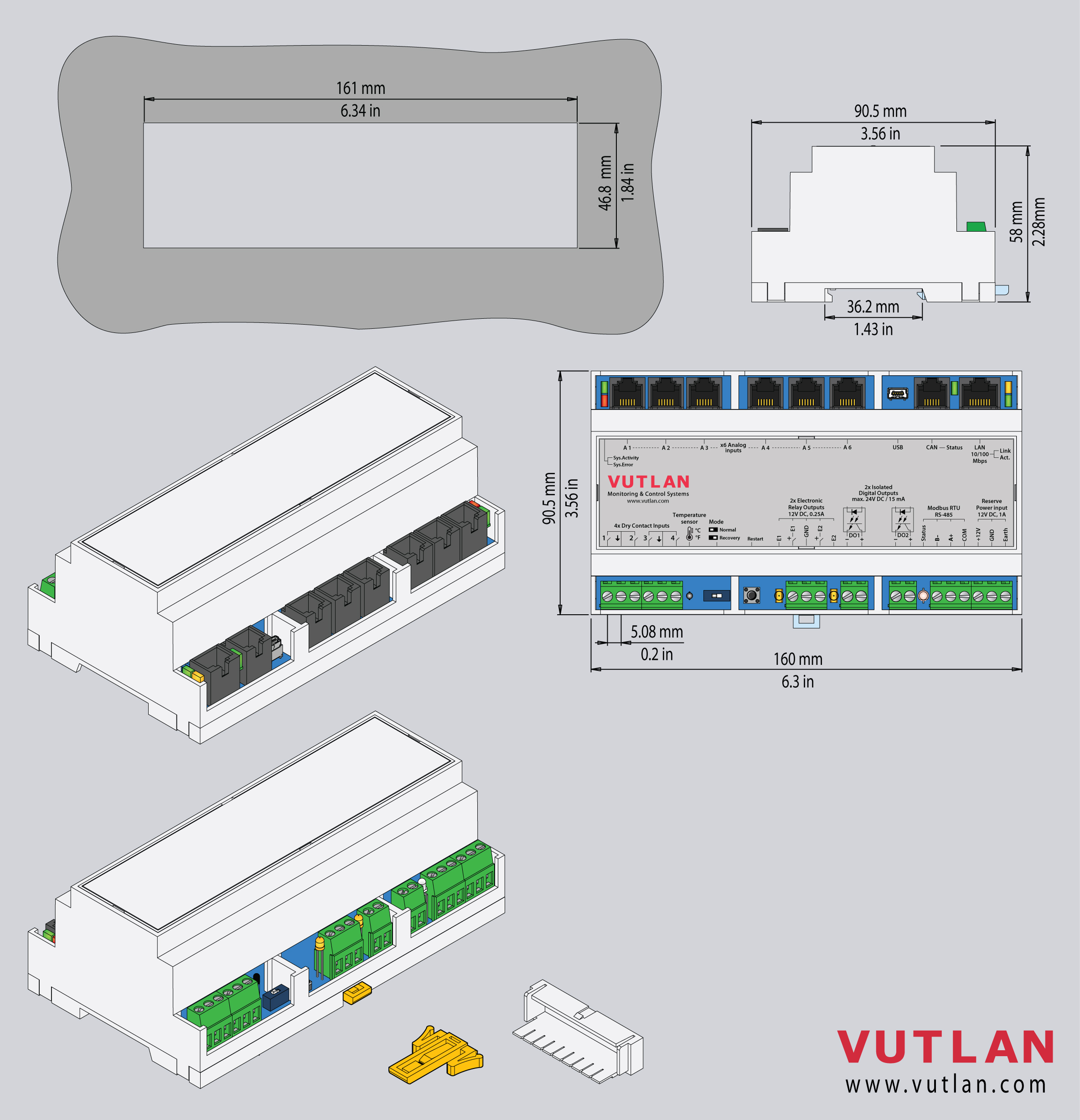

Dimensions

Function & Order options & Technical specifications

Product info is located on the product page "VT336 product page".

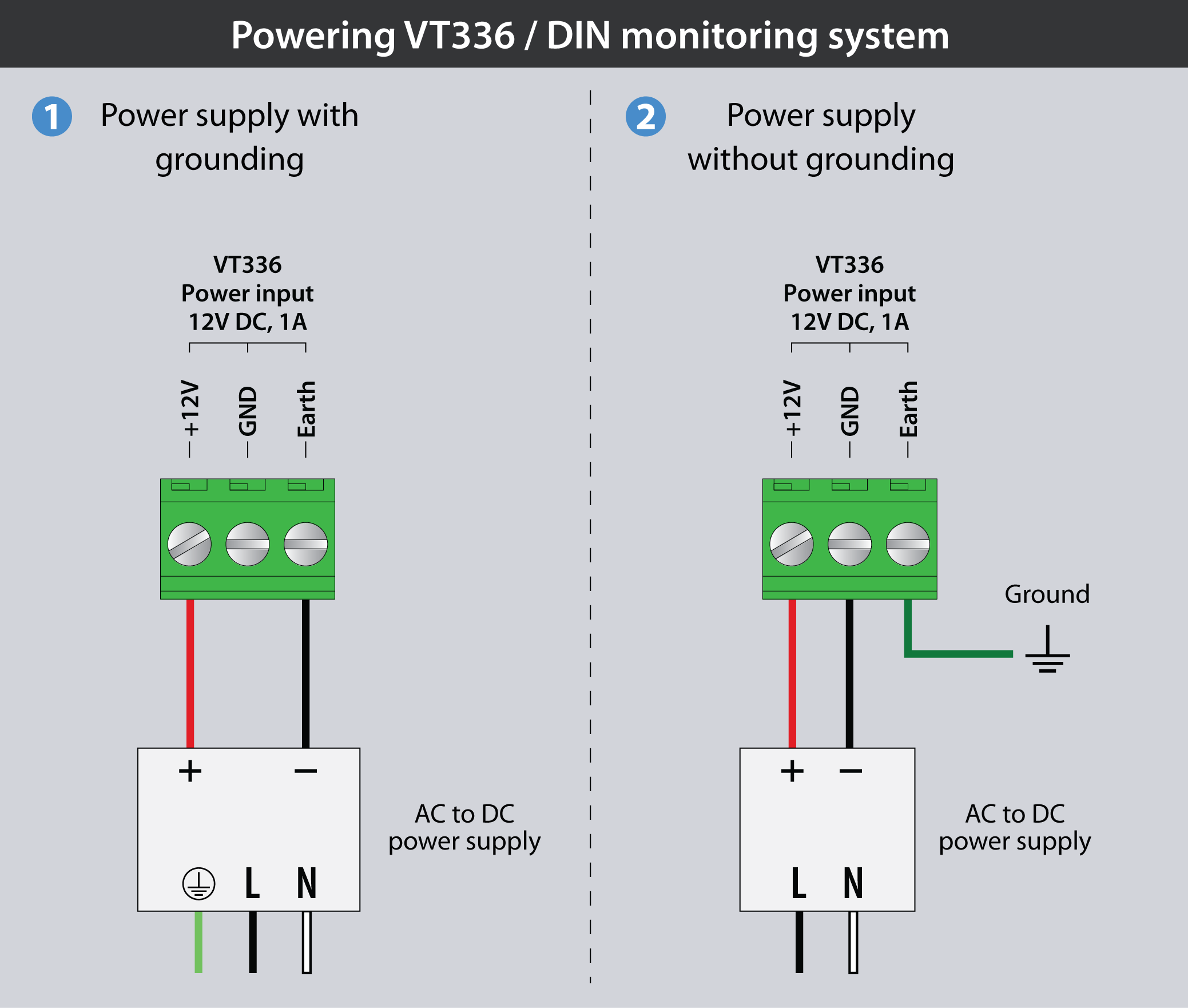

Powering the device

:

Power supply with grounding.

Power supply without grounding.

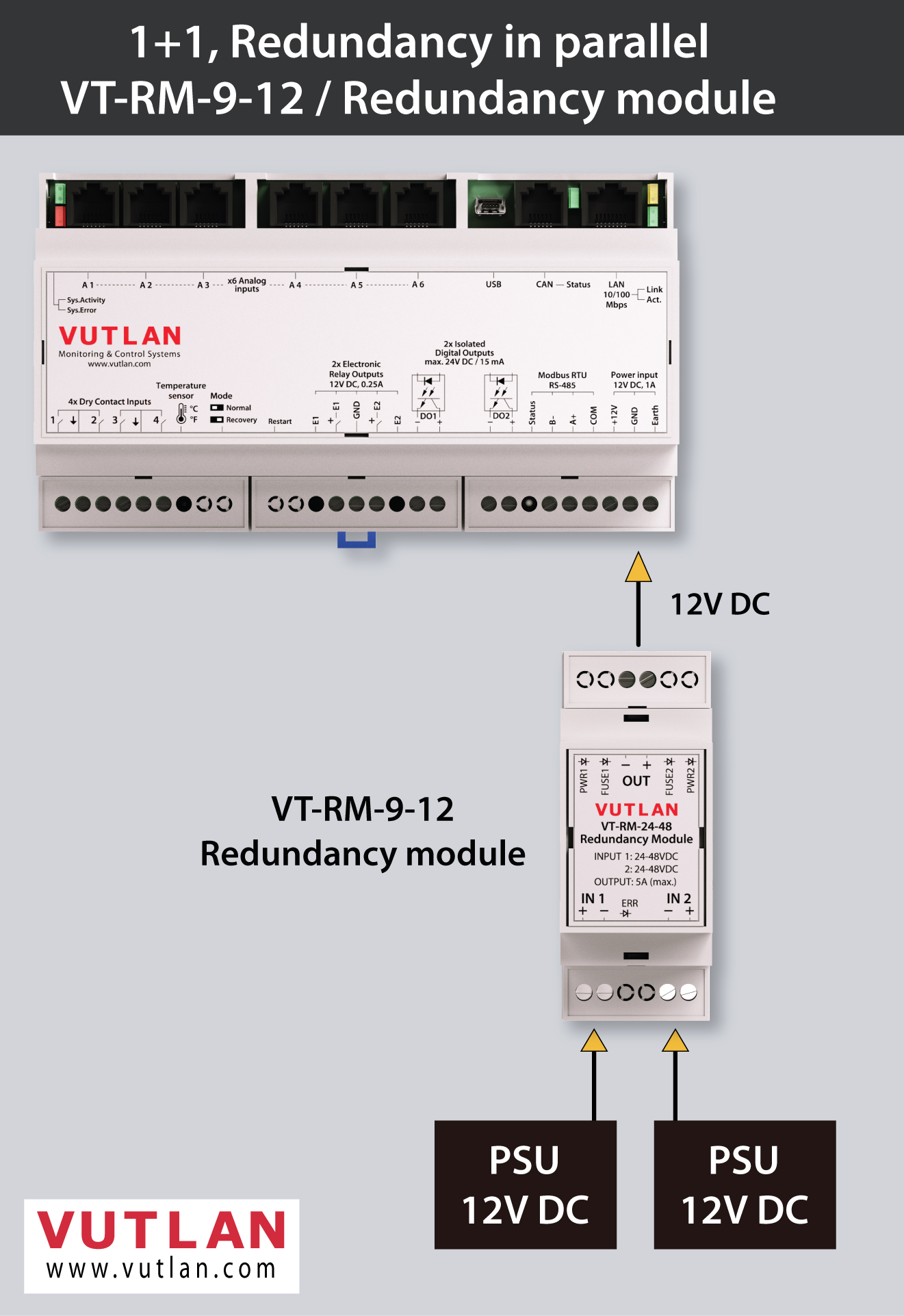

Powering the device using VT-RM-9-12 / Mosfet Redundancy module

VT-RM-9-12 decouples the outputs of the power supplies (9-12VDC, Max. 5A). Automatically supplies load current (Smooth Switchover) from the system input supply with the higher voltage.

Inventory

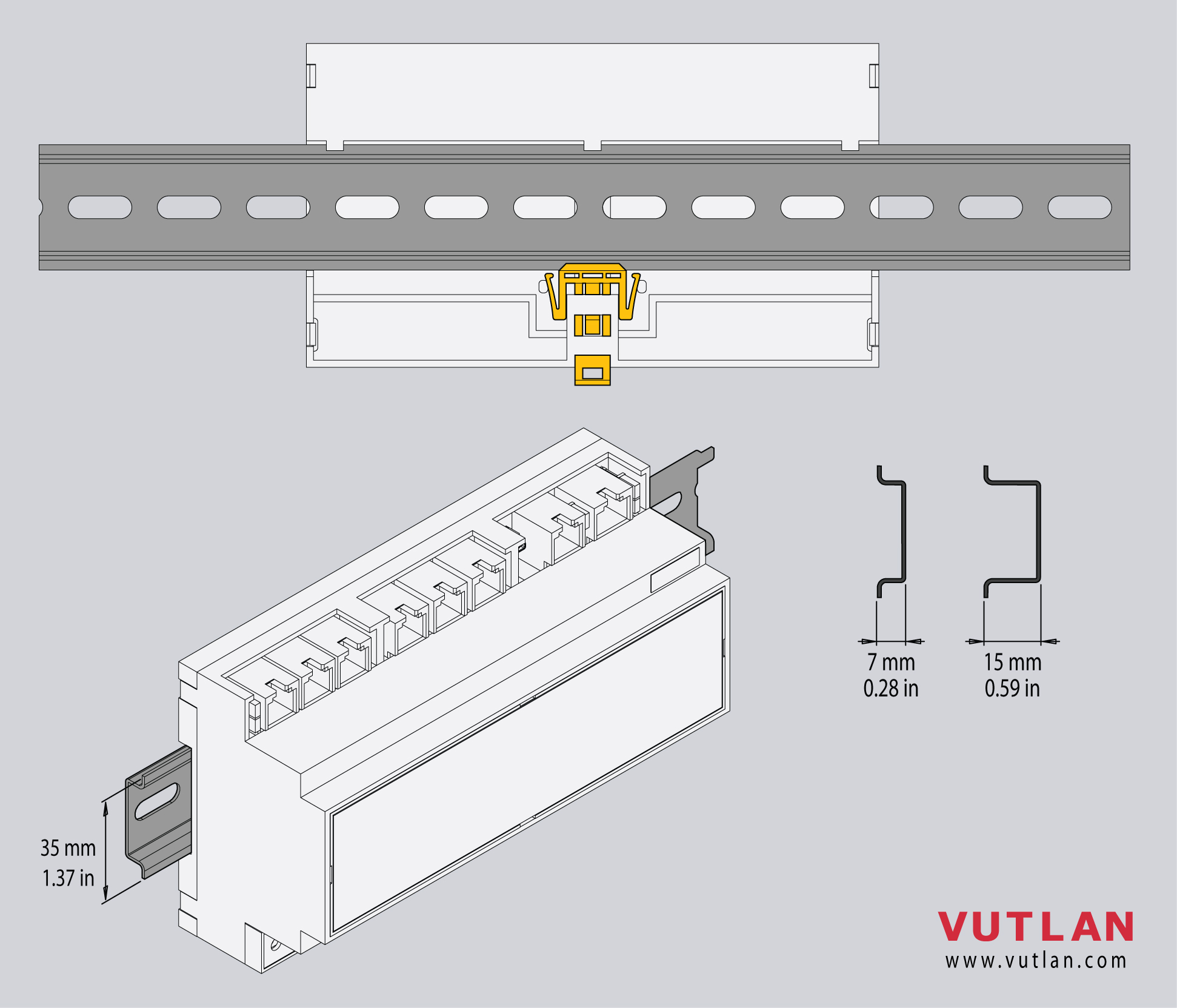

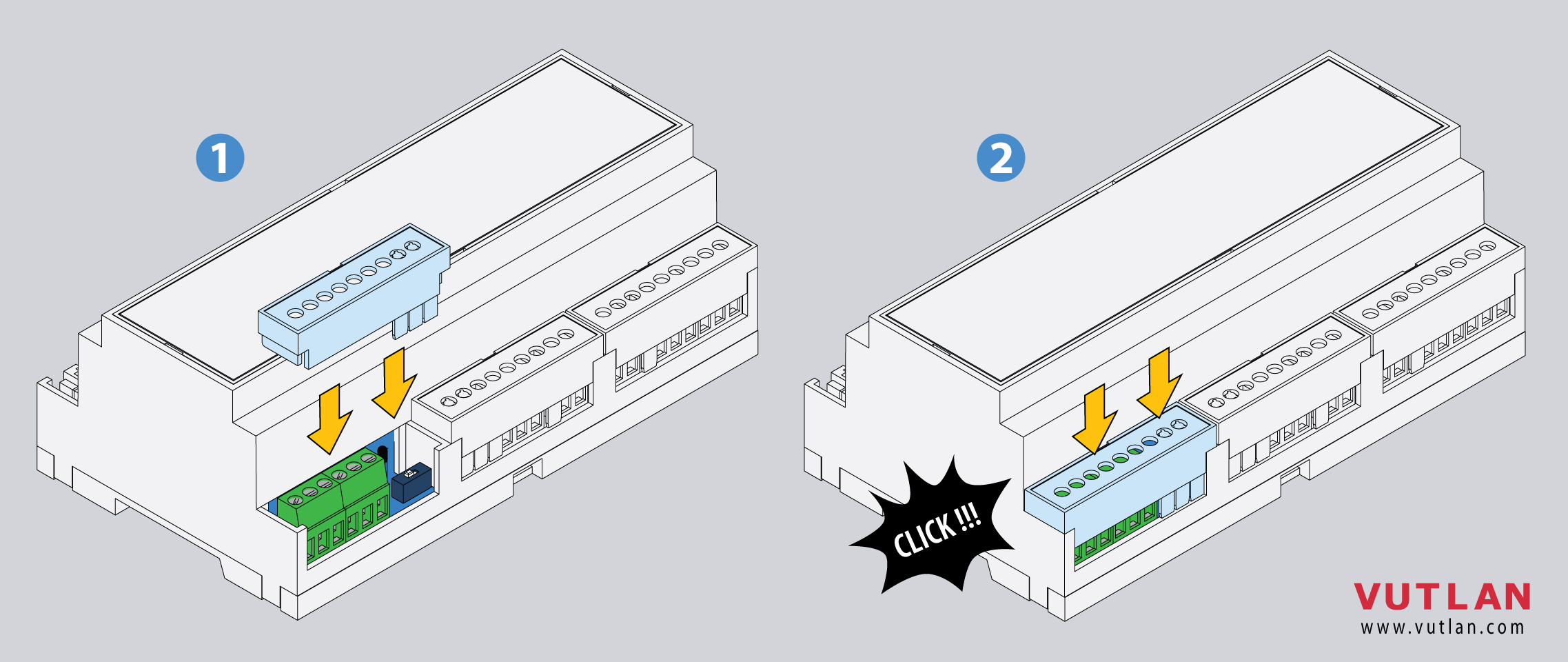

Mounting the device on a DIN rail

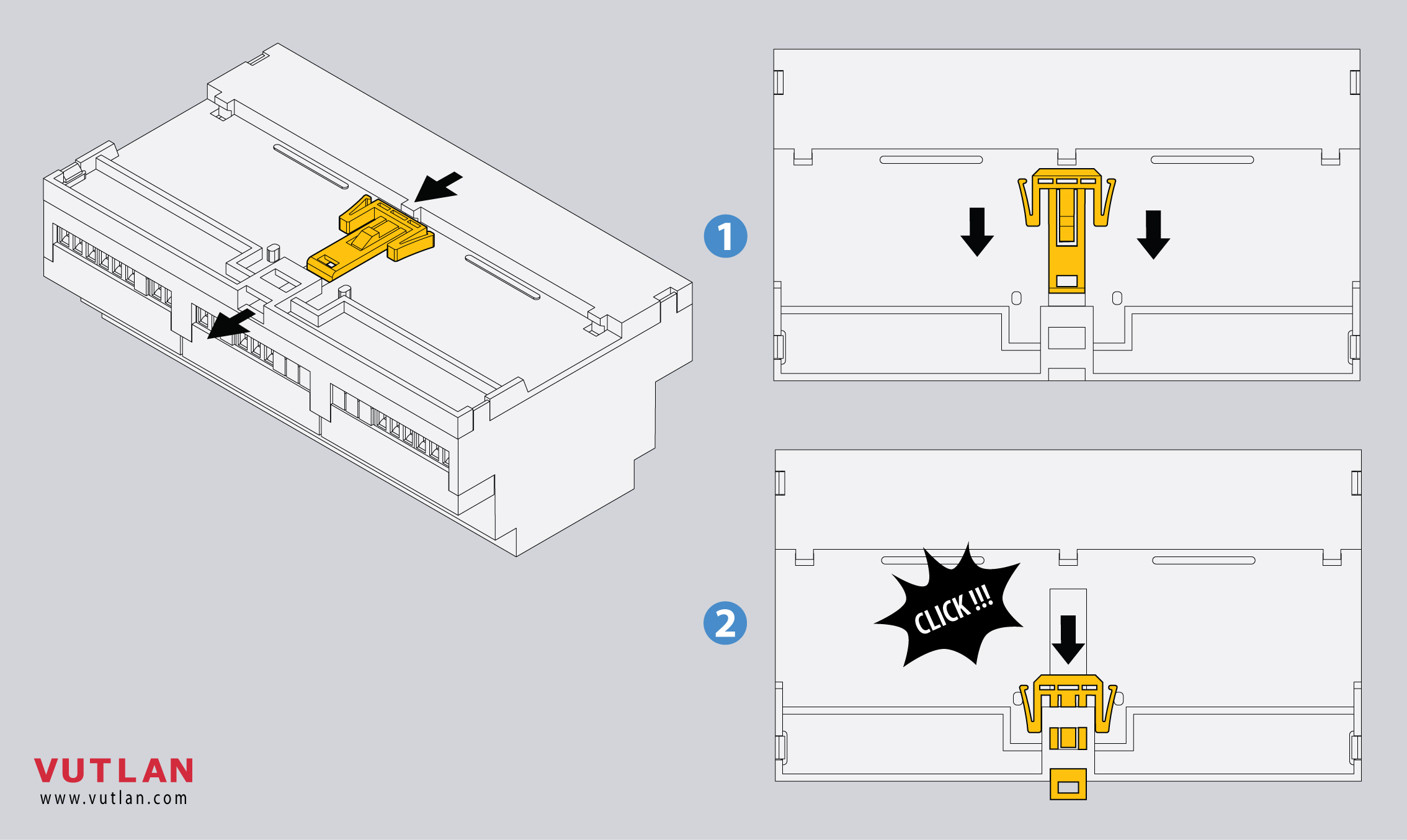

| 1 | Insert the DIN rail holder as shown in the picture | |

| 2 | Press the module onto the DIN rail, it should snap. | |

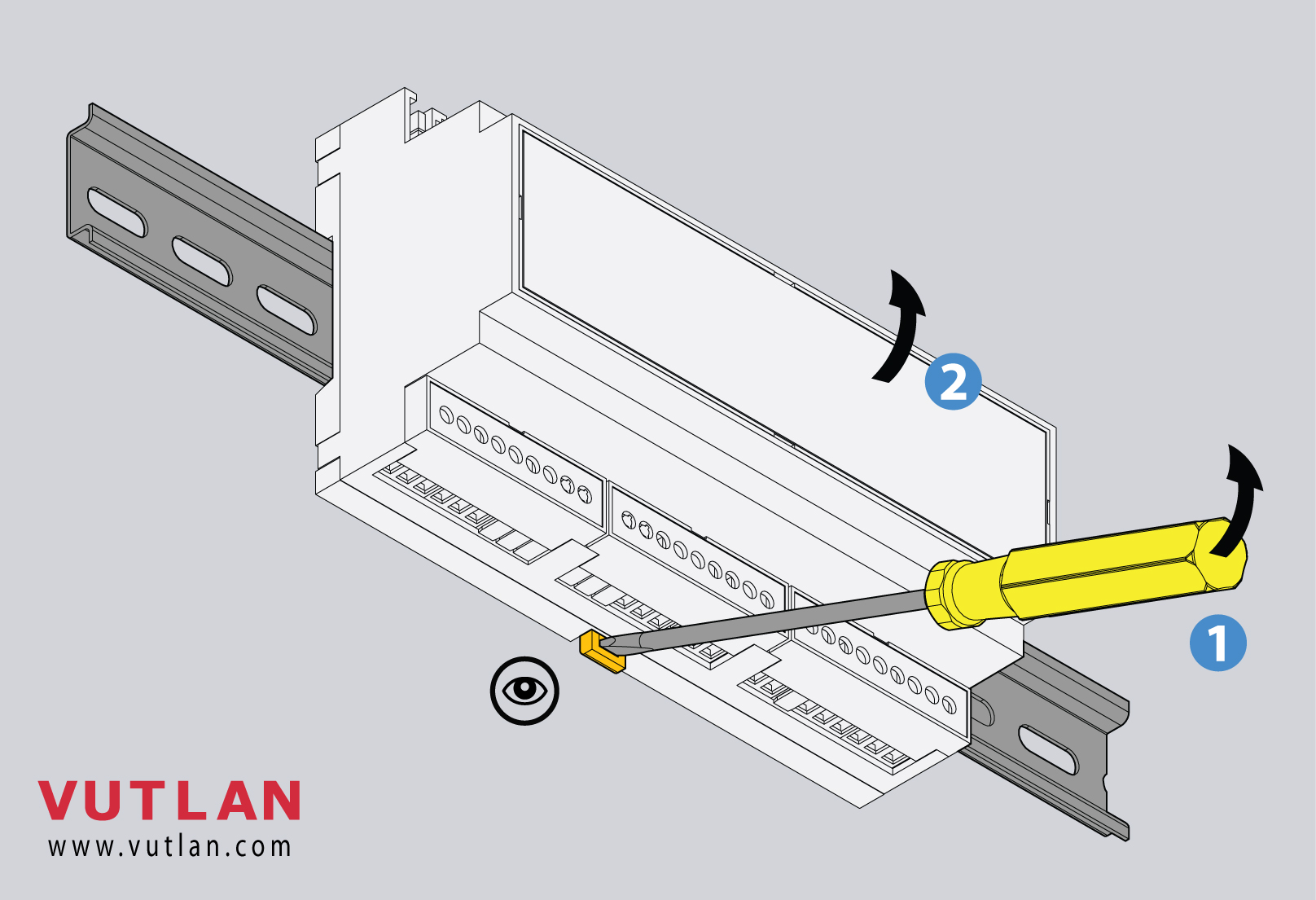

| 3 | To dismantle the unit from the DIN rail:

|

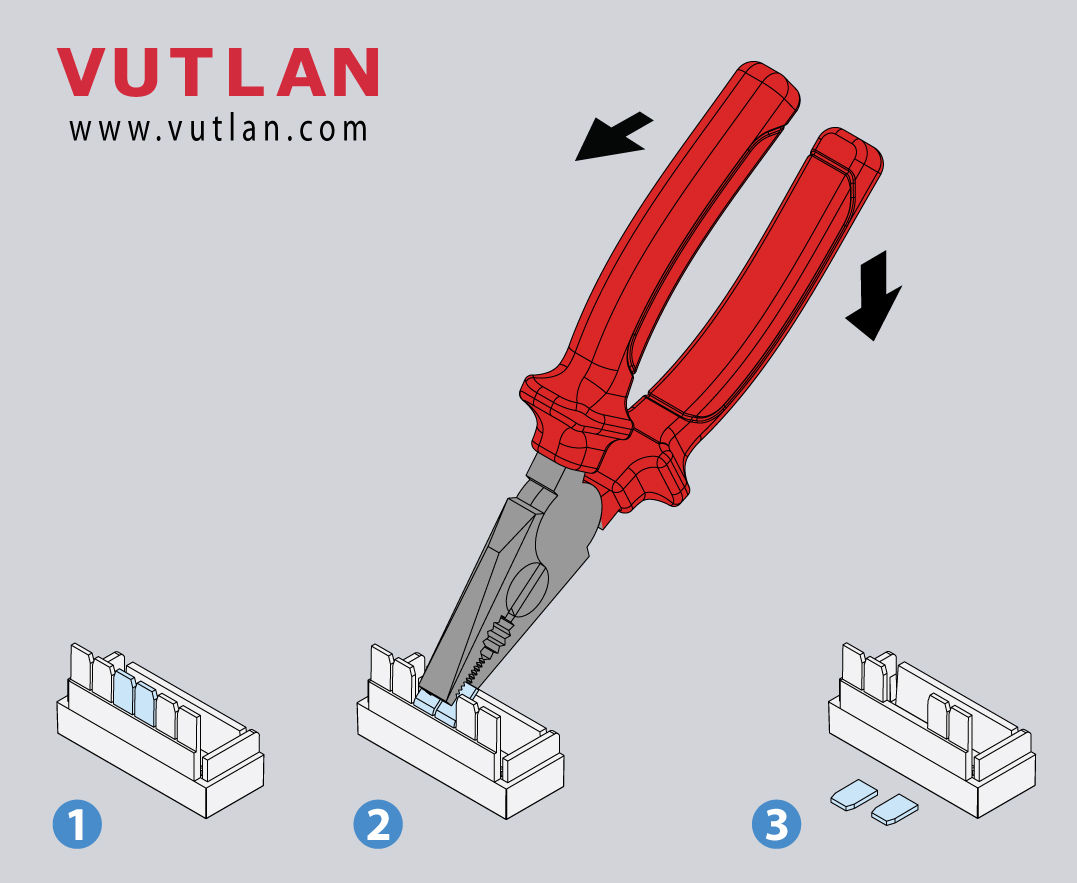

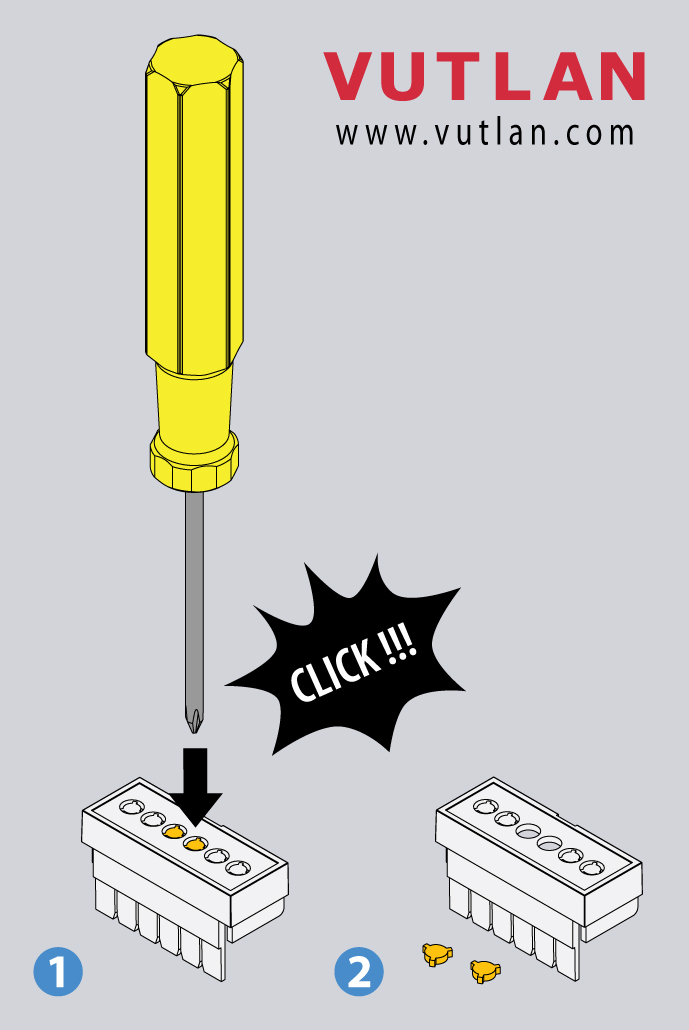

Mounting enclosure guards

| 1 |

| |

| 2 | Simply slide it inside the empty spaces until it clicks. | |

| 3 | Use a screwdriver to pull it out. |

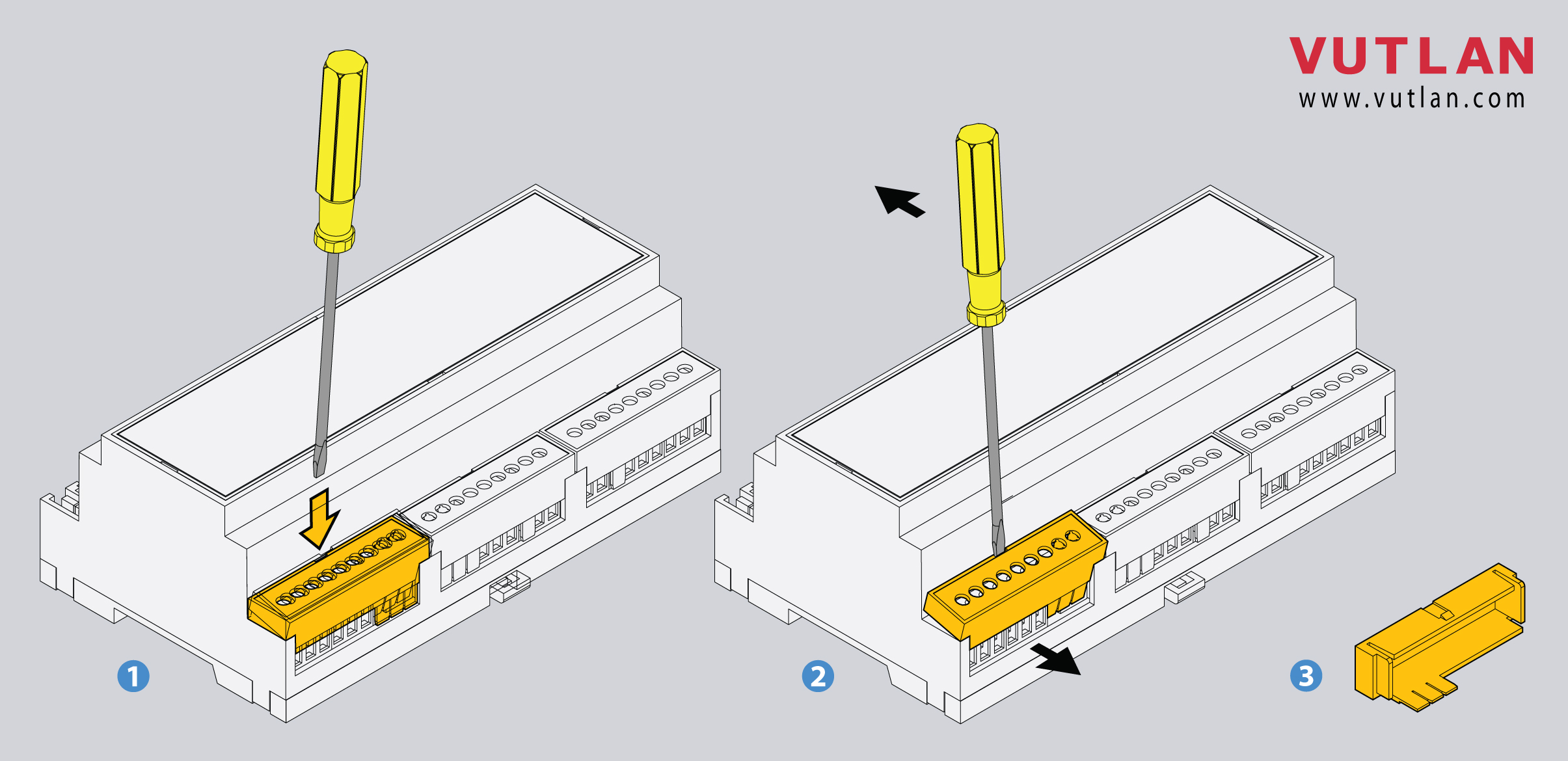

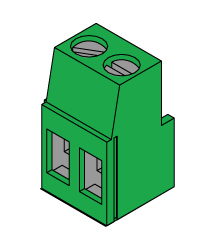

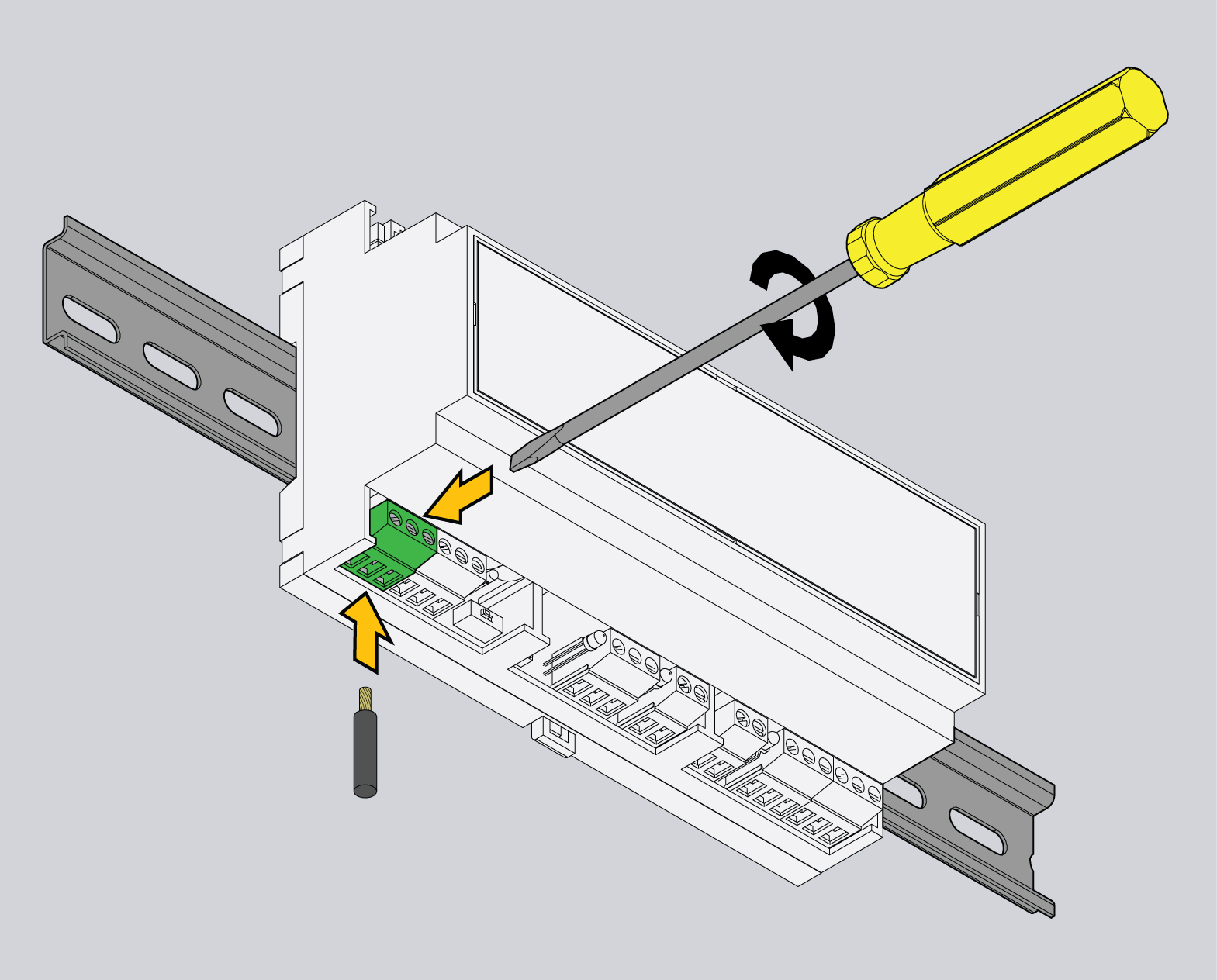

The system uses terminal blocks for several interfaces:

x4 dry contact inputs

x2 Electronic relay outputs

x2 Isolated digital outputs

RS-485 Modbus RTU

Power supply input

They share the same characteristics.

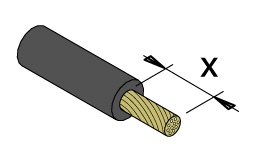

Specifications | Strip length | Wire cross-section | Screw head | |

|---|---|---|---|---|

Terminal blocks Step: 5.08 mm | 6 - 7 mm 0.23 - 0.27 in | 2.5 mm² 0.09 in² #26 - #12 AWG | Flat 3.5 mm 0.13 in | |

Using the table above, you can mount the cables.

Device configuration

Developer notes: